New & Used Office / Fiber Optic Trailers for sale Nationwide- TrailerTrader

Explore 182 New & Used Office / Fiber Optic trailers across all 50 states. Featuring top manufacturers, multiple pull types, and a range of GVWR options. Find the perfect trailer wherever you are.

Enhanced Listings

2018 Spartan Cargo Ev8.5-24t5ts-dd General Trailers in Dunedin, FL

-8.5X 24 ENCLOSED TRAILER -6" EXTRA HEIGHT -5200 LB AXLES -60" TRIPLE TONGUE -SPLIT AXLE UPGRADE -DOT TAPE ON SIDES...

Trailer Overview This is a tandem-axle enclosed cargo trailer customized as a splicing trailer. Base Trailer Specs * Tires: 15"...

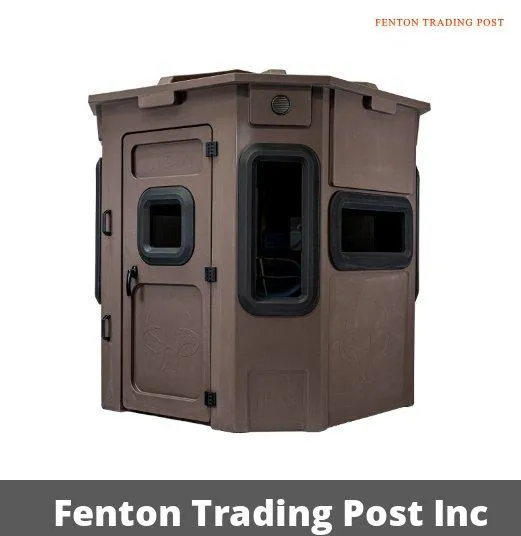

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

Trailer Overview This is a tandem-axle enclosed cargo trailer customized as a splicing trailer. Base Trailer Specs * Tires: 15"...

7X12 WHITE TANDEM AXLE EXPEDITION SERIES CARGO CRAFT XP7122 VIN 4D6EB1221TC070686 - FRAME AND STRUCTURE 11G FRAME EXTENDED HITCH GENERATOR...

6X10 WHITE TANDEM AXLE EXPEDITION SERIES CARGO CRAFT XP6102 - 4D6EB102XTC070690 - FRAME AND STRUCTURE 11G FRAME EXTENDED HITCH GENERATOR...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

CARGO CRAFT 6X10 WHITE TANDEM AXLE ELITE FLAT SERIES OFF-ROAD SPLICING TRAILER CARGO CRAFT EF6102 - 4D6EB1026TC070671 - FRAME AND...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

CARGO CRAFT EF7122 OFF-ROAD FIBER SPLICING TRAILER - 7X12 WHITE TANDEM AXLE ELITE FLAT SERIES - 11G Frame Extended Hitch...

CARGO CRAFT XP-7122 Fiber Splicing Trailer - Cabinets / Shelving 7' x 12' Expedition Series - GVWR 7,000 - FRAME...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...

Titan Blinds are manufactured BY hunters, FOR hunters. When Titan Blinds began designing their now famous line of hunting blinds,...